FHWA-Approved Pavement

Preservation Technique

Join Our List!

Get occasional updates on projects, tips you can use, events and webinars.We’ll never share your information and you can unsubscribe any any time.

Hot In-Place Recycling Blog

The Impact of COVID-19 on Road Resurfacing Budgets

While COVID-19 has had a major impact on every aspect of our lives, perhaps one of the biggest changes we’ve seen is a halt to our daily travels. With everyone from professionals to school children shifting to remote activities and a huge reduction in basic activities like social outings and family gatherings, people just aren’t out on the road. According to AAA, prices of gas have dropped $.37 per gallon cheaper than the same time last year, resulting in the lowest fuel cost the US has seen in a decade.

THE ROAD NOT TAKEN

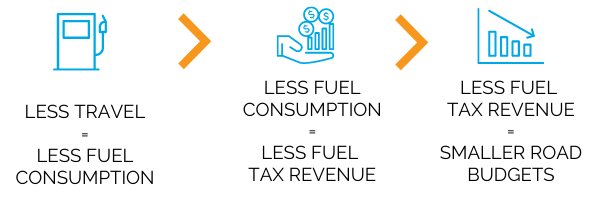

While lowered gas consumption has surface-level benefit for the consumer in the form of lowered gas prices, there are long term implications in the form of tax revenue streams. Here’s what that looks like.

Patrick McKenna, president of the American Association of State Highway and Transportation Officials (AASHTO), is predicting 30% nationwide decrease in transportation revenue. This means reduced budgets for road management and transportation projects. What’s worse is that we don’t even have a clear understanding of the full impact on road maintenance funds yet due to so many unknown variables about the situation.

The challenge is that while budgets are being reduced, roads still need maintenance. The factors that impact the life cycle of asphalt that are not relieved by the lower vehicle traffic include:

- Moisture

- Freeze/thaw cycles

- Traffic for essential employees and travel

- Age

So while budgets are shortened, the amount of roads that need to be serviceable for essential workers (and hopefully more regular traffic patterns in the near future) remains the same. Additionally, roads that don’t receive the proper maintenance and repairs can suffer from long-term degradation as surface levels wear down and the underlying structure is eventually compromised.

City managers, directors of public works and county engineers are facing a challenging situation that will require a new solution to an old problem that’s getting worse due to unprecedented circumstances. What we’ve always done in the past isn’t going to work anymore because we don’t have a choice anymore. It’s time to find something better.

IT'S TIME TO LEVERAGE HOT IN-PLACE RECYCLING

Here's how it works!

.png?width=600&name=HIR%20Process%20Graphic%20(1).png)

- The preheater drives over existing asphalt and preheats the asphalt to approximately

320 degrees Fahrenheit. - Replasiticizing oil penetrates the asphalt and a rejuvenating agent is applied to re-activate the existing liquid asphalt.

- The heated asphalt is disrupted with spring-loaded steel tines to a depth of 1.5”

- The revitalized asphalt is replaced on the road through a traditional asphalt screed in a single pass

- A vibratory steel drum roller is used to compact the recycled asphalt to a specified density

- The public agency completes the resurfacing process with surface treatment choosing from

options such as microsurfacing, chip seal, slurry seal or hot mix overlay.

The entire process can frequently be done for less money* in less time, without complicated lane closures and with a smaller carbon footprint than the traditional mill and fill.

*Total savings depend on the final surface treatment selected + the local cost of asphalt per ton.

A DIFFERENT APPROACH

Hot In-Place Recycling is here to help you navigate the challenges unique to the impending budget shortfalls while avoiding unhappy drivers, accidents and damage liability and long-term damage to roads. Here’s how Hot In-Place Recycling can help you weather the storm of COVID-19:

1. Reduced Costs

HIR can help you save up to 34% on your road resurfacing to help you pave more miles for less money. This means you can stretch

your reduced budgets further than the traditional mill and fill process and do more road work with the limited budget you have.

2. Reduced Time

Hot In-Place Recycling can resurface 10,000 square yards per day, start to finish. Our nimble and quick process means the ability to quickly respond to changing workplace safety guidelines and restrictions.

3. Comparable Service Life

3. Comparable Service LifeReduced budgets can mean being tempted to find band-aid solutions that are temporary and aren’t good long-term investments of the public’s money. Hot In-Place Recycling saves time and money by recycling the existing asphalt, which doesn’t compromise on quality or service life.

THIS IS THE TIME TO FIND BETTER SOLUTIONS

1. ALL (OR MOST) TRUCKING IS ELIMINATED

Because HIR reuses 100% of the existing pavement, the only trucking involved depends on what the agency chooses to put on top. A hotmix overlay afterwards would require some trucking. However, many choose surface treatments such as microsurfacing or chip seal, which are essentially truckless.

2. FEWER STEPS

It’s hard to change the way things have always been done. Now is the time to strike when the iron (or asphalt) is hot. It’s time to work with a company:

- With 93+ years of experience in asphalt

- That has leveraged the power of an innovative process

- That has been proven to reduce project cost, time and carbon footprint without reducing the life cycle of the end result.